Unveiling the Role of Metal Foundry in Automotive Manufacturing

Wiki Article

Exploring the Art of Metal Casting: Strategies and Applications in Modern Foundries

Metal casting is a classic craft that incorporates virtuosity with design accuracy. From ancient methods to modern developments, this procedure has evolved significantly. Numerous methods, such as sand casting and lost-wax casting, showcase the adaptability of the medium. Meanwhile, technologies like 3D printing are improving exactly how factories run. As the lines in between performance and virtuosity blur, one should consider how these developments effect both modern applications and typical practices. What exists in advance in this evolving landscape?The Basics of Metal Casting

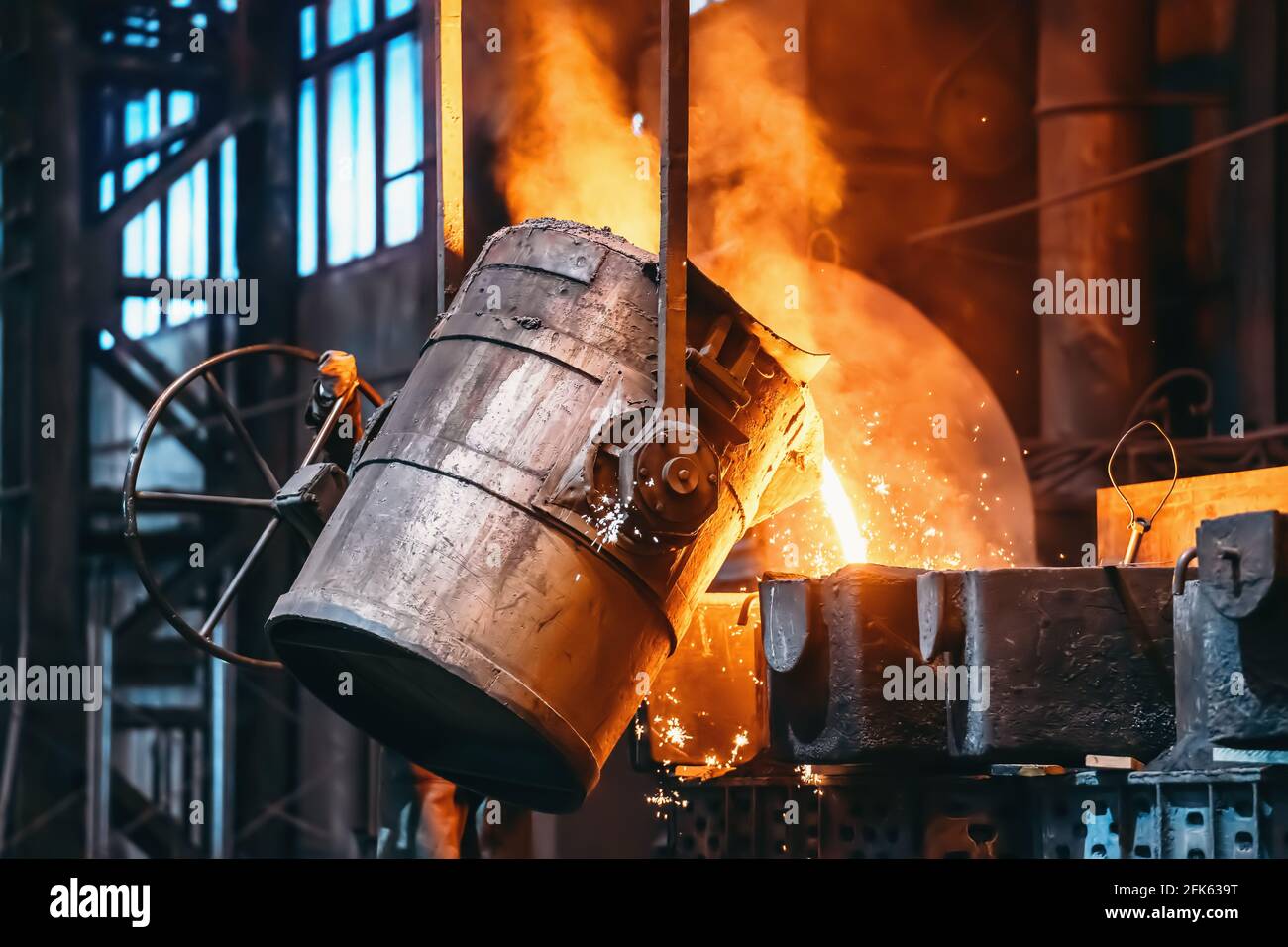

Metal casting, a pivotal process in production, entails putting liquified metal right into a mold to accomplish a preferred shape. This method works as a structure in the manufacturing of complicated steel elements across different sectors. Crucial element of steel casting consist of the option of materials, which can vary from light weight aluminum to steel, each selected for its certain buildings and application viability. The procedure begins with mold creation, which can be made from sand, metal, or porcelains, depending upon the casting approach made use of. The molten metal is after that very carefully poured into the mold and mildew, where it cools and strengthens. Vital variables such as temperature level control, cooling price, and mold design considerably affect the end product's high quality and qualities. On top of that, recognizing the physical and chemical homes of the steel aids in optimizing casting efficiency, inevitably enhancing the effectiveness of the manufacturing process and making certain premium outcome customized to particular requirements.Traditional Casting Techniques

Traditional casting strategies incorporate a selection of methods that have actually stood the examination of time, demonstrating their performance in generating detailed steel elements. One famous approach is sand casting, which employs a mixture of sand and a bonding representative to produce mold and mildews. The versatility of sand casting enables the manufacturing of varied forms, making it suitable for both small-scale and massive production. Another remarkable strategy is financial investment casting, typically made use of for precise and complicated geometries. This approach includes producing a wax pattern that is coated in a ceramic covering, which is after that heated up to get rid of the wax, leaving a dental caries for liquified steel. Additionally, pass away casting is utilized for high-volume manufacturing, where molten metal is injected right into multiple-use metal mold and mildews. Each of these standard techniques continues to be relevant, showcasing the workmanship and ability integral in the art of steel casting, while satisfying the demands of different markets.Modern Innovations in Metal Casting

As sectors advance, advancements in steel casting are reshaping production processes and improving efficiency. Advanced modern technologies such as 3D printing and computer-aided style (CAD) are reinventing mold development, enabling complex layouts that were previously unattainable. These techniques facilitate rapid prototyping, fostering and reducing lead times creative thinking in item development.Furthermore, the combination of automation and robotics in factories is improving operations, reducing human mistake, and increasing security. Smart sensors and real-time tracking systems allow specific control of temperature and product properties, guaranteeing greater top quality outcomes.

Furthermore, sustainable practices are emerging, with the use of energy-efficient furnaces and recycled materials, lowering ecological impact. The adoption of composite materials and sophisticated alloys is also increasing the possibilities of metal casting, leading to more powerful and lighter parts. In general, these modern developments are transforming metal casting right into a more efficient, exact, and eco accountable industry.

Applications Across Various Industries

While diverse sectors significantly rely on metal casting, the strategy's flexibility plays an important function in conference certain application needs. In the auto market, metal casting is essential for creating engine components, transmission housings, and other detailed components that require precision and durability. The aerospace industry advantages from light-weight casted components, making certain both efficiency and gas performance. In addition, the building industry makes use of steel casting for architectural components, such as beams and supports, enhancing the integrity of structures and bridges.

Furthermore, the power industry utilizes steel casting for wind turbine blades and various other significant machinery that should stand up to severe conditions. Clinical gadgets additionally see applications of metal casting, specifically in surgical instruments and prosthetics, where precision is critical - Metal Foundry. Generally, the flexibility and integrity of metal casting make it crucial across numerous fields, adding to the improvement of technology and facilities in modern-day Metal Foundry culture

The Artistic Side of Metal Casting

Usually connected with industrial applications, steel casting additionally locates its location in the domain name of art, where skilled craftsmens change molten metal right into detailed layouts and expressive sculptures. This artistic side of steel casting incorporates varied techniques, consisting of sand casting, lost-wax casting, and financial investment casting, each offering one-of-a-kind possibilities for imagination. Artists make use of these methods to generate jobs that range from abstract types to realistic depictions, enabling individual expression and commentary on modern problems.

Frequently Asked Concerns

What Security Actions Are Necessary in a Steel Casting Foundry?

Important safety and security measures in a metal casting shop consist of personal safety equipment, correct ventilation, emergency situation protocols, training in handling molten steels, routine equipment maintenance, and clear interaction of dangers to ensure employee safety and security and health and wellness. Metal Casting.Exactly How Do Ecological Rules Effect Metal Casting Processes?

Ecological guidelines greatly influence steel casting procedures by mandating using cleaner innovations, minimizing emissions, and promoting waste administration practices. Compliance commonly calls for investments in devices, training, and alterations to existing treatments to lessen environmental influence.What Are the Typical Problems in Metal Spreadings?

Typical defects in metal spreadings include porosity, shrinking, additions, and misruns. These concerns can occur from improper mold and mildew design, poor temperature control, or contamination, inevitably influencing the structural honesty and overall quality of the end product.How Is Waste Managed During Metal Casting Manufacturing?

Waste monitoring in metal casting manufacturing entails recycling scrap metal, implementing efficient material use, and using innovative technologies to decrease waste. Shops adopt methods like sand recovery and correct disposal techniques to reduce environmental influence.What Profession Opportunities Exist in the Metal Casting Sector?

The steel casting sector offers diverse job opportunities, including roles such as foundry manager, metallurgical designer, high quality control inspector, pattern maker, and production manager, dealing with numerous ability and knowledge in making procedures.Metal casting, an essential process in production, entails pouring liquified steel into a mold and mildew to accomplish a desired form. Furthermore, pass away casting is used for high-volume production, where liquified steel is infused right into recyclable metal molds. While varied sectors progressively count on metal casting, the method's adaptability plays an essential role in conference particular application requirements. Often associated with commercial applications, metal casting also discovers its place in the domain name of art, where competent artisans transform molten steel right into expressive sculptures and detailed layouts. Waste monitoring in metal casting manufacturing entails recycling scrap steel, implementing efficient material usage, and using advanced technologies to reduce waste.

Report this wiki page